Products

CGF series impact crushers are widely applied in metallurgy, building materials, chemical industries. They are ideal for crushing medium hard brittle materials of coarse, secondary and fine crushing stages, such as limestone, dolomite, sandstone...

Product Specifications

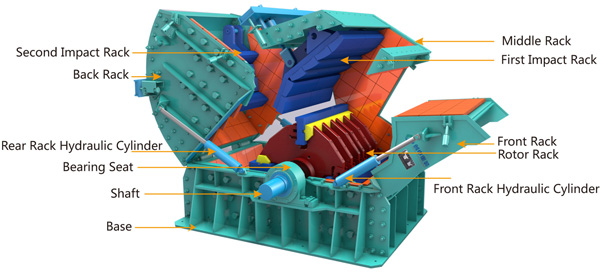

CGF Series Impact Crushers Structure diagram

a.Real time monitoring on the abrasion of the blow bar, and the primary and secondary impact plates are executed, so that a reminder for replacement of them can be released in time.

b.The size of the discharge opening can be automatically detected, and then the positions of the primary and secondary impact plates can be adjusted by using the hydraulic system, to ensure the stability of the product size.

c.Intelligent Control on the Feeding Quantity

d.Real time monitoring on the bearing temperature, which helps to discover abnormal conditions in time and execute timely maintenance, so that the service life of the bearings can be prolonged in a result.

e.Real time monitoring on the equipment vibration is executed, so that the equipment can be shut down and warning messages can be delivered automatically under circumstances like iron-pass, blow bar fracture, or loose anchor bolts etc.

f.Real time monitoring on main shaft speed is executed, so that the equipment can be stopped and warning messages can be launched automatically when there is belt sliding or motor fault.

g.The front and rear racks can be opened hydraulically, which can facilitate maintenance and replacement of the wearing parts greatly.

h.The equipment has networking function.

Product Inquiry

| Product Name: | |

| Full name: | |

| Phone: | |

| E-Mail: | * |

| Content: | * |

| Verification code: | |

About Us|Contacts|Disclaimer|sitemap

Copyright©Shanghai Unitruston Intelligent Technology Co., Ltd Website Building : Trueland